| S.No |

Facility |

Description |

Image |

| 01 |

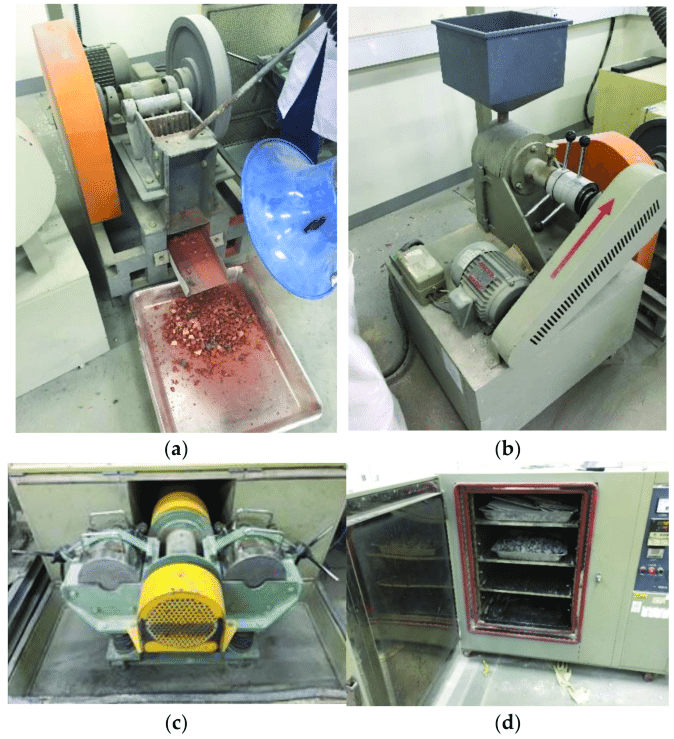

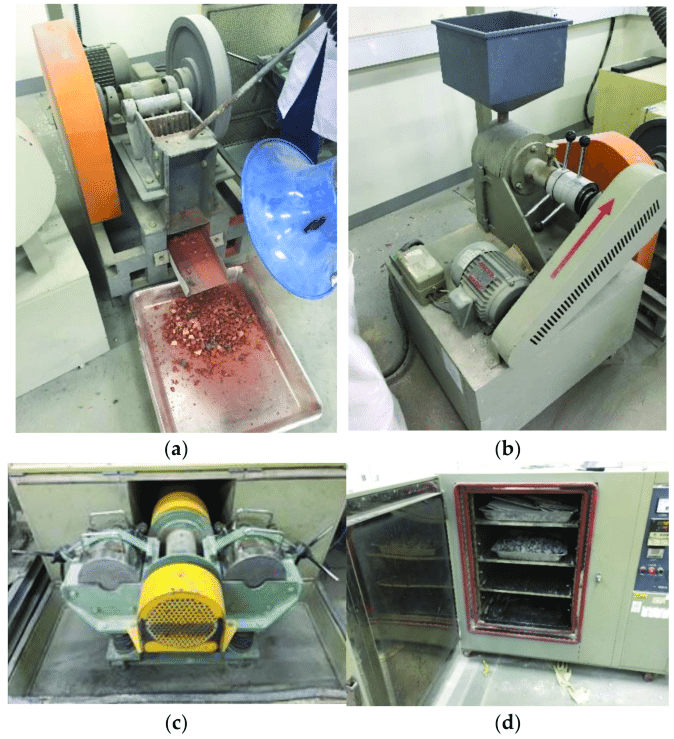

Crushing and Grinding |

Raw materials are crushed and grounded to exact dimensions. |

|

| 02 |

Seive Analysis |

This process analyses the quality of the raw materials. |

|

| 03 |

Monolith |

This process converts various raw materials to a homogeneous mixture. |

|

| 04 |

Bagging |

The processed materials are packed as per the customers requirements. |

|

| 05 |

Muller Mixer |

The batch materials are mixed with additives in this process resulting in a homogeneous mixture. |

|

| 06 |

Pressing |

To press the materials with high pressure and mould the product directed based on customers requirement |

|

| 07 |

Green brick loading |

Green bricks are loaded into a tunnel klin for the firing process. |

|

| 08 |

Firing |

Firing process would be carried out as per the quality benchmark set by the customer. |

|

| 09 |

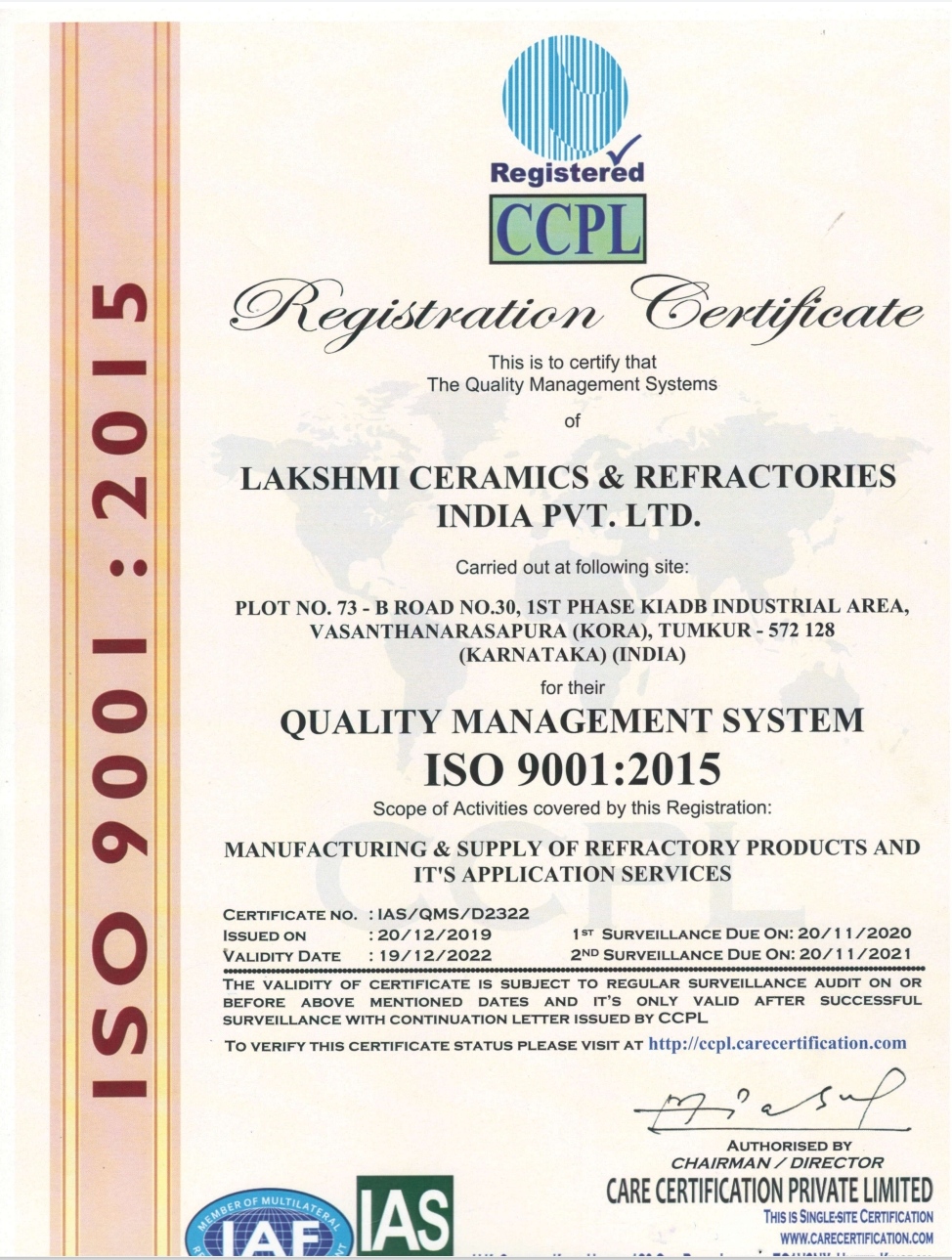

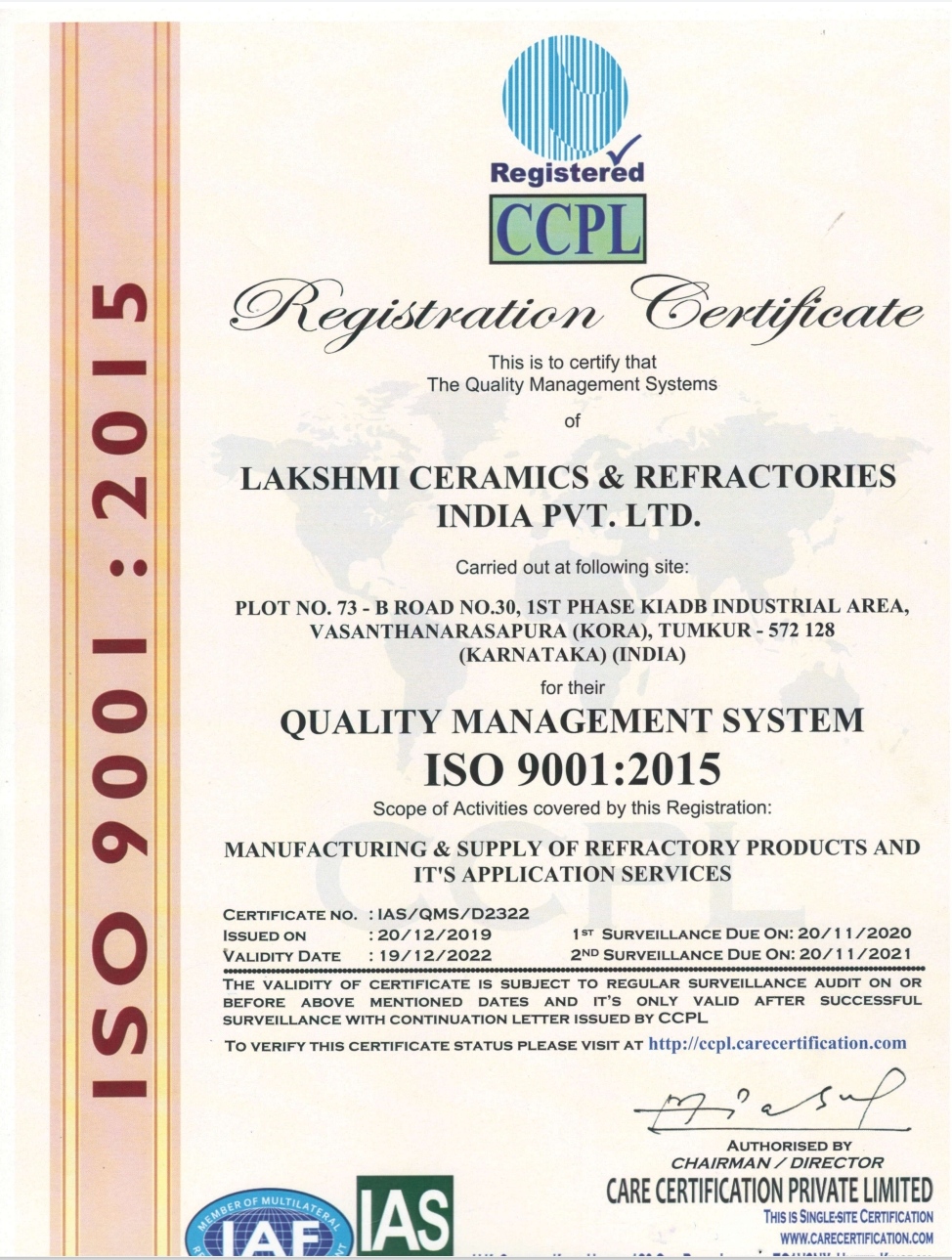

Certification |

We are certified as per ISO standards. |

|

| 10 |

Chemical Lab Analysis |

Ensures the product chemical quality as per the customer’s requirement in the lab. |

|

| 11 |

Unloading |

Careful unloading of the materials from the tunnel klin. |

|

| 12 |

CCS Lab Analysis |

To ensure the products physical properties. |

|

| 13 |

Sorting |

Material sorting and sampling based on the customer’s requirements. |

|

| 14 |

Stockyard |

The finished products would be sorted and stored in the stockyard for faster delivery. |

|

| 15 |

Inspection |

Inspecting the finished products to ensure the physical property and quality of the product |

|

| 16 |

Lab Clearance and certificate |

Technical inspection will be carried out as per customer’s requirements and the material will be provided with a test certificate. |

|

| 17 |

Packing |

The packaging is done as per the standards set by the customers. |

|

| 18 |

Dispatch |

Materials will be dispatched from the stockyard. |

|